Inspection Equipment

-

Magnetic flux leakage & ultrasonic testing line

Functions: It can realize the function of bidirectional detection, wall thickness measurement and layered defect detection.

-

High Temperature Rupture Creep Testing Machine

Functions: used to test the mental and non-mental, such as tension, compression rupture, relaxation test, high temperature tensile, etc.

-

600T Flattening Machine

Functions: test the ultimate plastic deformation of a metal tube under a given condition without a crack defect.

-

1000KN microcomputer-controlled electro-hydraulic servo universal testing machine

Functions: Stretching, flattening, flaring and bending test

-

X-ray fluorescence spectrometer

Functions: Able to analyze metal, slag specimen, oil, etc. With standard-sample-free software, it can make qualitative analysis of the unidentified matter

-

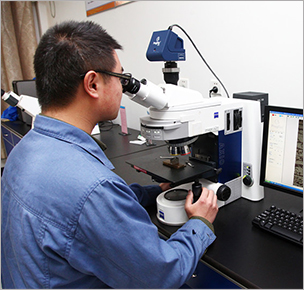

Zeiss upright (inverted) microscope

Functions: Used to observe metal metallographic structure and non-metallic inclusion, etc.

-

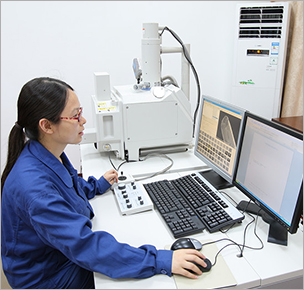

Scanning electron microscope / energy disperse spectroscopy

Functions: Microscopic analysis, micro elements semi-quantitative analysis

-

Microcomputer-controlled pendulum bob impact testing machine

Functions: Measure the instantaneous characteristic of the material during the impact process and record characteristic curve.

-

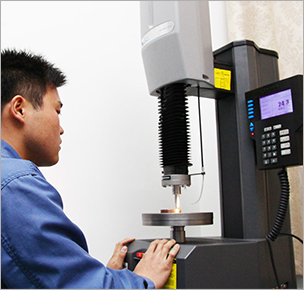

Digital Display Wilson Rockwell Apparatus

Functions: Applicable to Rockwell hardness test of ferrous metals, non-ferrous metals and non-metallic materials.

-

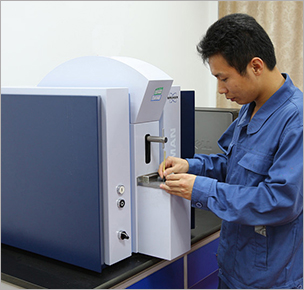

Brooke direct-reading spectrometer

Functions: Component analysis of steel sample. It can analyze the chemical component of iron-based, aluminum-based, cooper-based, and nickel-based metal products. The equipment is with small sample excitation (able to analyze samples with diameter not less than 1mm).

-

FOERSTER& GE flaw detection line

Functions: detect metallic surface defects.

Contact

- Henan BEBON Iron&Steel co., ltd.

- 0086-371-86151827

- 0086-371-86011881

- [email protected]

Online Consultation

Online Consultation