Quality Control

Production Process

Billet: Bbn Refined Billet By Ourselves

Cutting Pipe: Cutting The Billet Material According To Customer’s Length Requirement, So That The Finish Rolling Seamless Steel Tube Length Can Meet Customer Requirements.

Feeding: Billet Material In The Chain To The Annular Furnace

Heating In Rotary Heating Furnace: Austenitizing The Internal Organization Of Billet, Convenient And Perforation.

Conical Piercing: Solid Core Billet Be Out Of The Annular Furnace, Then Piercing As Tubular Billet, There Are Pressure Perforation, Push And Skew Rolling Rolling Perforation.

Blowing Nitrogen Spraying Borax: Prevent The Inside Surface Of Pipe From The Infolding Etc Defects, To Prevent Some Defects Like This.

Limited Moving Core Bar Rolling: The Tubular Billet After Piercing,Control The Tubular Billet Wall Thickness, That Is, Finished Product Wall Thickness.

Extracting Mill: After The Mandrel From Rolling Through The Chain From Tubular Billet.

Re-Heating: Prevent Steel Tube Cold Too Fast, Convenient And Reducing

Descaling By High Pressure Water: Get Rid Of The Tin Oxide From The Appearance

Stretch Reducing: Control Of Its Outer Diameter, That Is, Finished Product Outer Diameter

Cooling On Cooler: Air Cooling, Cooling

End Cutting: Cutting The End Uneven Material.

Pipe Cutting: Cut The Finished Length;The Length Of The Customer Need.

Straightening: The Pipe From Cooling Bed Have Certain Bending,Eliminate The Bending.

Suck Ash: Absorb Dust From Both The Surface And Inside Of The Steel Tube

Flaw Detection: Check Whether Seamless Steel Tube Inside And Outside Surface With Flaws, Eliminate The Defective Pipe.

Manual Inspection: Inspection Outside Diameter, Wall Thickness, Length, Bending And So On, So See If Meet The Standard Or Not.

Weighting: Each Pipe Will Be Weighting, The Real Weight Will Be The Same As Mtc.

Marking: According To The Standard On The Tube Body Spray, We Can Also According To Customer Requirements Do The Spray Mark, The General Content Are Mill Name, Heat Number, Batch Number, Specification, The Pipe Number, The Serial Number Of The Customer Request, Customer Can Check The Detailed Information Of Each Tube According To The Mill Certificate At Any Time

Warehousing: The Qualified Product In Warehousing System, Complete The Last Procedure.

Production Control

Before Production: Raw Material Control

BBN Refined Billet By Ourselves. We Will Send Sample To Our Testing Center Do The Composition Inspection Before Production

In Production: Production Process Control

Fully Appropriate Quality Target Management System, Reliable Quality Guarantee System, Perfect And Effective Quality Management System

After Production: Inspection And Process Control

Heat Treatment, Eddy Current Testing, Ultrasonic Flaw Detection, Hydraulic Pressure Test And So On, Strictly According To Standard And Customer’s Requirement

Inspection Before Shipment:

Quality Is Our First Concern From The Very Beginning To The End. It Is Monitored In Every Step Of Our Work. Apart From Strict Quality Supervision System In Mill, Before Shipment, We Do More Inspection Work To Guarantee Maximum Perfection Of Our Products. The Inspection Mainly Includes Dimension Check, Marking Check, Visual Quality Check, Packing Check, Document Review, Etc. If It Is Convenient To Our Customers, We Warmly Welcome Customers Join Our Inspection Work.

We Must Ensure Every Piece Of Product Fully Meet Quality Requirements, Or It Will Be Reworked Until Pass Inspection Of Every Step.

Our Qc Department Must Issue The Test Report To The Sales Department Every Time, In Order To Ensure The Quality Of Each Shipment.

Third Party Inspection

Over The Past Ten Years, We Have Built Solid Business Ship With Most Third Party Inspection Organizations. The Representatives Are Sgs, Bv, Intertek, Tuv, Pmi, Bv,Lr, Gl, Rina, Abs, Ccs, Nk, Dnv, Kr, Etc.

Scope Of Inspection: Quality Check, Packing And Storage Check, Marking Check, Visual Quality Check, Dimension Check, Document Review, Quantity Verification, Chemical Composition Analysis, Tensile Test, Loading Supervision, Etc.

We Arrange Third Party Inspection According To Customer Instruction. After Inspection, The Official Test Report Will Be Published If Test Result Approved.

Quality Control Problem Case

35crmo Steel Pipe Quality Problem:

We Receive One Order Is 35crmo Seamless Steel Pipe In October, 2015. The Promise Delivery Time Is 30 Days. After Production, Our Technical Team In Mill Test The Quality Again. It Is Regret To Find The Hardness Is a Little Higher.

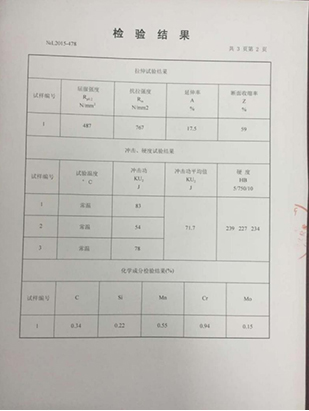

Unqualified Test Report:

Our Company Solution:

Firstly, We Inform This Information And Test Report To Customer Immediately. We Check With This Customer Whether They Can Use This Product. If They Can’t Use, Could They Wait For Another 7 Days For Re-Production. After Negotiation With Their Engineer, The Customer Can’t Use This Products.They Prefer To Re-Production.

Secondly, Once We Got Update News From Customer, We Inform Our Production Manager. We Produce The Products Again For Free. We Tried Our Best To Prepare The Billets Quickly. The Production Is 7 Days. We Test Before Transportation.And We Also Support Customer’s Inspector Test The Quality Again. The Quality Is Applied To Standard And Customer’s Requirement.

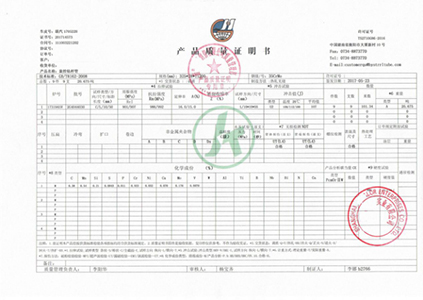

Qualified Mill Test Certificate

At Last, In Order To Make Up For Customer’s Losses Because Of One Week Delay Delivery, We Have Offer Some Compensation To Our Customer.

Contact

- Henan BEBON Iron&Steel co., ltd.

- 0086-371-86151827

- 0086-371-86011881

- [email protected]

Online Consultation

Online Consultation